Hey Everyone! Hope you enjoyed your weekend and are ready for another busy work week! I know the NumberCruncher blog has been on a bit of a hiatus the last couple of weeks, but we're back and ready to Crunch through these long hot South Florida summer days. During these summer months our Support Team has been hard at work answering our current clients questions and helping setup All Orders by NumberCruncher on new client's networks. The grind never seems to slow down at our offices, especially during summer, when companies are reevaluating their current Inventory Management software and are deciding if its up-to-par or if their needs are not being met or satisfied. If your company is in the midst of reevaluating your software, please remember that NumberCruncher provides all prospective clients with an hour-long demo to make sure our software is a perfect fit, as well as, a 30-day no commitment FULL software trial before you decide to buy. We don't want your company buying our software, if it isn't the ideal fit for your business. To Learn more about ALL ORDERS please click HERE or give us a call at 866-278-6243 TODAY!

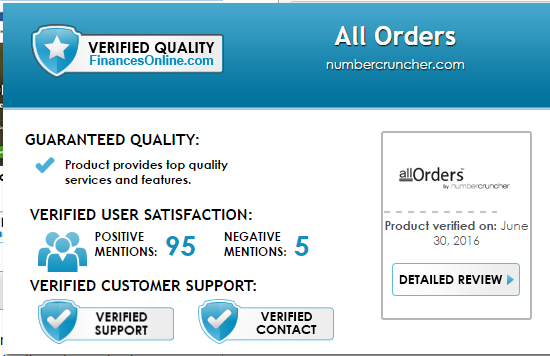

Recently, All Orders by NumberCruncher got featured on a number of websites. To begin the month, Financesonline.com wrote a review and named ALL ORDERS as one of their Rising Stars for 2016. Finances Online also recognized All Orders with their Great User Experience Certificate & Award.

NumberCruncher.com would like to thank Financesonline.com for recognizing us and writing a review on All Orders. Finances Online is the fastest growing independent review platform for B2B, SaaS and Financial Solutions.

Also this month, Scott Gregory of Better Bottom Line: the QuickBooks Expert, included NumberCruncher in his "Can QuickBooks Handle My Inventory?" guide. Scott is a certified QuickBooks Expert who has worked with QuickBooks software for 15+ years and knows a thing or two about QuickBooks add-on solutions. For him to feature NumberCruncher is his guide, is a big deal to us!

To check out the FREE Inventory guide or to learn more about QuickBooks solutions, please visit BetterBottomLine's website HERE.

Refresh, Relax & Reconnect at the 2017 NumberCruncher Retreat

The NumberCruncher team has also started planning a NumberCruncher Retreat here in Sunny South Florida, during the rough Winter months. Details are being finalized and you can expect an official announcement VERY SOON! If you are interested in attending or know someone in your company who will be interested, please send me an email at jgoldberg@numbercruncher.com with the details, so i can add you to our Pre-Announcement Blast. By being a part of our Pre-Announcement Blast, you will be the first to receive the event flyer and registration information, ALSO, you will receive a special prize during the Retreat, for being part of our Pre-Announcement Blast List.

The purpose of this Retreat is too allow our clients a refresher on the NumberCruncher family of products, an introduction to our NEWEST software and most importantly a chance for us to reconnect with our loyal customer base, in a relaxing, stress-free, Sunny and HOT environment; while the rest of the country is getting hit by Winter storms.

Follow our Blog, Website and Social Media channels (Twitter, Facebook, Linkedin Company Page, Linkedin Group) to stay up-to-date on the latest developments of the NumberCruncher Retreat.

SMALL BUSINESS APP SHOWDOWN

Finally this week, NumberCruncher has entered our All Orders software into the 2016 $100,000 Intuit Developer Small Business APP Showdown with the winner being announced at QuickBooks Connect 2016 being held in October in San Jose, California.

More information on how to vote, will be published in an upcoming BLOG post, an email blast & our Facebook/Twitter pages. In Order to WIN, we're going to need the help of our Loyal Cruncher Family! Please follow our Blog/Social Media pages, to find out about some perks we are offering for those clients who vote for us, in the $100,000 Intuit Developer Small Business APP Showdown

More information on how to vote, will be published in an upcoming BLOG post, an email blast & our Facebook/Twitter pages. In Order to WIN, we're going to need the help of our Loyal Cruncher Family! Please follow our Blog/Social Media pages, to find out about some perks we are offering for those clients who vote for us, in the $100,000 Intuit Developer Small Business APP Showdown

The next NumberCruncher Blog will feature a sneak peek of our newest software, that we are releasing at the beginning of next year (2017)! Make sure you check back next week for the latest on Order Time!